When it comes to building an outdoor oven, you may start feeling like one of the proverbial three little pigs when you try to decide what type is best.

Will you build it out of mud? Concrete? Stone? Brick? Unlike the porcine story, however, there’s no downside to choosing any of these building materials, and no wolf will come howling at your backyard to blow the structure down. (Instead, these beautiful and long-lasting ovens will likely only attract friends, family, and neighbors!)

Now, if you decide to emulate little pig number 3, you may find that a brick oven suits your backyard aesthetic best. These ancient baking chambers can range from small constructions built near the back deck to massive, backyard-dominating creations that will catch eyes and whet appetites as they demonstrate your masonry prowess.

We’ve collected information and photos from all around the world to show you the ins and outs of building your very own outdoor brick oven.

What is an Outdoor Brick Oven?

What an outdoor brick oven is should be fairly self-explanatory – an oven that is constructed of bricks and is built outside of your house. As you will see in the pictures accompanying this article, these ovens vary greatly in size – some are fairly small contraptions that will hold a single pizza, while others are much larger and can handle multiple loaves of bread. And it should be mentioned that while not beyond the capability of a competent DIYer, brick ovens are certainly more difficult to build than something like an outdoor earth oven. However, if you have any experience building with masonry or if you are willing to learn, don’t let the difficulty of the task frighten you.

What are the Different Types of Outdoor Brick Ovens?

An outdoor brick oven works in a similar manner to any other masonry oven whether indoor or out. Some of these brick ovens are fairly lightweight (as far as masonry-style ovens are concerned) and specifically used to make pizza (or flatbread). Others are very massive structures that can be used to bake a larger assortment of baked goods (most typically bread).

While it is possible to make a small brick pizza oven off-site and then have it moved to the final location, most all of these brick ovens are built on site and are then immovable.

The pizza ovens do not need to be hugely massive as it is the fire that bakes the pizzas. The oven itself is just a structure that holds the fire and its heat in a certain area. As they do not need to be so massive, they are simpler to make than their larger cousins. Many of these are just a single layer of brick thick.

The bread ovens must incorporate a large amount of mass in its design. It is the thermal mass of the oven that will do the cooking, so you will need to build your oven using an adequate amount of brick. Use too little, and you will end up with nothing but mostly raw dough.

Whatever type of brick oven you choose to build, it will become a centerpiece to wherever they are placed. Little else on your land will get as many comments and questions as a well-built outdoor brick oven. In order to highlight them and give people a place to congregate and relax while the food is being made, most people will build a nicely-bricked patio area around these ovens. There is just something about a piping hot fire blazing away inside these ovens that just draws people to them.

Some Design Considerations for Outdoor Brick Ovens

An outdoor brick oven is certainly more complicated than a simple pile of bricks with a space in the middle. These are well-designed devices that have a fair bit of engineering included.

1. Use the Correct Type of Brick

First of all, you must make sure that you use the proper type of brick in the construction of the oven. You need to remember that these ovens must endure very high amounts of heat and not every brick is up to the task. You can’t just go to the local hardware store and pickup a load of cheap paver bricks and expect to make an oven out of them. These are usually made of concrete and are liable to explode under the intense heat created in these ovens. For the parts of the oven that are in direct contact with the fire, you will need to use a special type of brick called a fire brick. They are a bit more expensive than other bricks, but they are a necessary cost. For all other parts of the oven, you can use normal clay bricks; you can even use the concrete bricks on the very external parts if you prefer.

2. Make the Opening of an Adequate Size

This may seem pretty straight-forward, and it is, but I figured it was worth mentioning as my first outdoor oven had an opening that was a bit too small. Sure it was sized correctly for proper draft and ease of making a fire, but one thing I didn’t think about was the size of the peel. Most peels that you can buy are of a certain size. If you want to be able to get your baked goods in and out of the oven easily, make sure the opening is larger than the size of the peel. Otherwise you will have to improvise like I did and make one yourself.

3. Decide if You Want a Chimney or Not

I must first say that a chimney on an oven is optional. My first outdoor oven did not have a chimney and it still made some of the best pizzas and flatbread I had ever had. However, there are some benefits to having a chimney that might make it worth the extra hassle. First of all, a well-designed chimney can improve draft. Without a chimney, the air and exhaust must pass through the same hole (the incoming air comes in the bottom and the exhaust passes out the top of the hole), but with a chimney the exhaust goes out a separate hole (the chimney) which lets you set up a unidirectional air flow. Usually, this chimney is higher up than the rest of the stove which also allows for better draft production. Finally, a chimney makes it so the hot gases and smoke are directed in whatever direction you want. If you do not have a chimney, the exhaust comes out the front hole, which is also where you happen to be standing. So when you are adding or removing food, all that hot exhaust and smoke comes out at your face.

4. Make Sure there is Enough Thermal Mass

As already mentioned, not all outdoor brick ovens need to be massive structures made from many hundreds of pounds of masonry. How much mass your oven needs depends on what you are planning on baking in it. If you are making an oven to specifically cook pizza or flatbread, you do not need to much mass. The oven needs to be little more than a container to hold the fire with the pizza since the fire, and not he mass of the oven, is doing the cooking. Bricks for a cooking surface, bricks for the dome of the oven, and a coating of some sort is all that is really required.

However, if you plan to ever use this oven to make real bread (as opposed to flatbread), you really need to make sure that it has adequate thermal mass. When you make bread in any sort of masonry oven, the fire is not present in the oven during the cooking of the bread. You use a hot fire to heat up the mass of the oven, and then the mass of the oven slowly releases all of that heat over the course of the baking process to cook the bread. The more thermal mass there is, the more heat it can hold. To accomplish this, you can either use a few layers of bricks, or you can have a layer of mud in between layers of bricks. Anything you can do to increase the mass in encouraged.

5) Decide What Sort of Covering is Needed

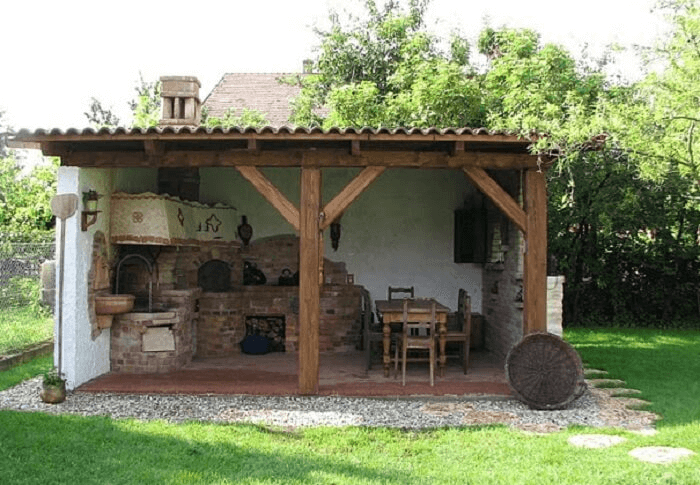

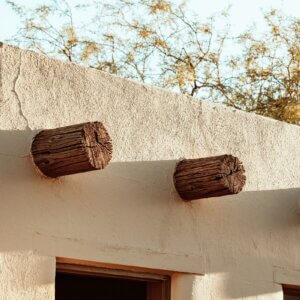

Remember that these ovens are built outside. This means that they are going to be exposed to heat and cold, rain and snow, and everything else that nature will throw at it. While a brick oven doesn’t necessarily need any sort of extra covering, it is probably a good idea to have one. The simplest covering would be some sort of tarp that can be put on when the oven is not in use. However, this is not the most aesthetically-pleasing covering. Most people prefer the look of an actual roof over their ovens. This doesn’t need to be a complicated affair to look good. But it will help keep the rain and snow off your oven and keep the burning sun off of you.

Gallery of Images and Helpful Links for the Intrepid DIY Brick Oven Builder

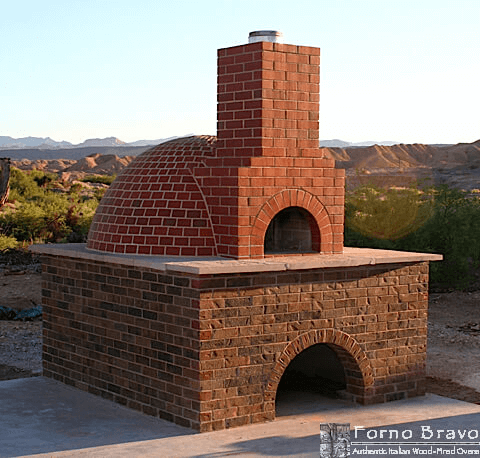

DIY Pompeii Brick Oven Kit from Forno Bravo (there’s tons of variations on this theme: check out their gallery of finished builds here)

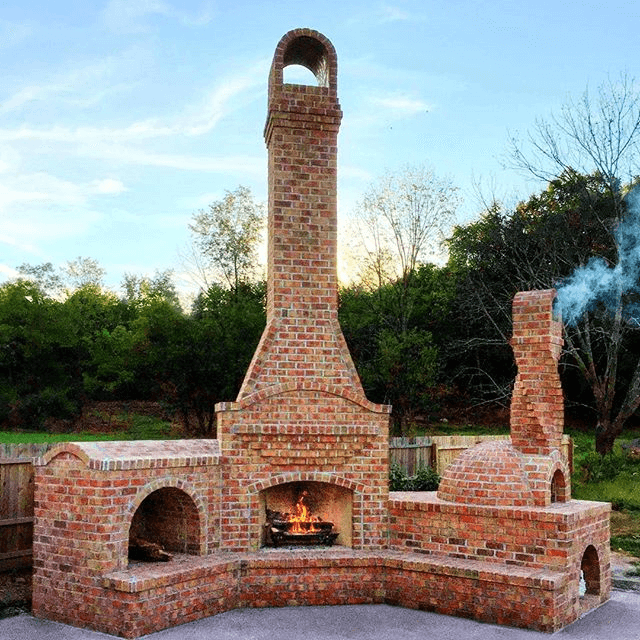

Here’s a round, beehive-style oven in North Carolina. The builder says that the bricks at the base were salvaged from an old chimney. See the whole build and narrative here.

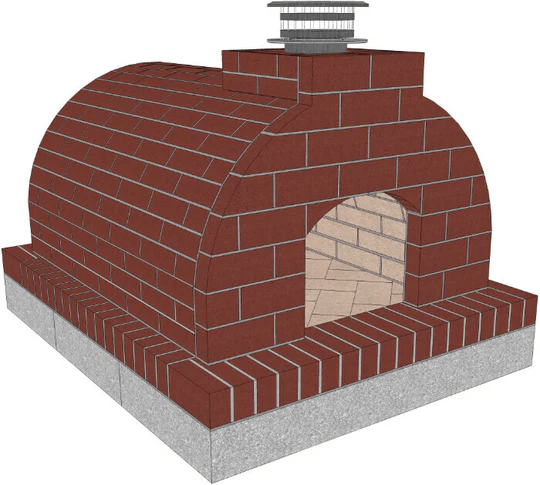

Alan Scott and Daniel Wing are co-authors of the excellent book The Bread Builders, (free to read at the link provided) part of which is dedicated to making the perfect oven for baking the best bread. Pictured above is a so-called “Alan Scott” brick oven, and here is a link to some free plans to build your own.

Here’s a company that you can order pre-assembled and masonry kits from. Bear in mind, these will cost you quite a pretty penny, but they take out a lot of the guesswork for the convenience.

You can buy a concrete interior for your oven here, then build a brick structure around it as you desire. Again, anticipate that these kits are going to be pricier than figuring it out on your own!

Here’s another company that offers pre-fabricated concrete interiors.

This website is a bit painful to navigate, but it has some of the most detailed step-by-step photos of an oven build we’ve found.

Outdoor Brick Oven Kits and Plans

Types Of Outdoor Oven Kits

There are numerous different types of kits to construct the central oven itself:

- Multiple prefabricated ceramic parts.

- Multiple prefabricated concrete parts.

- A single cast piece of concrete.

- A single prefabricated oven unit.

Materials For DIY Oven Projects

DIY center oven can be made from:

- Hearth slab and mortared fire brick.

- Hearth slab and cob. (See cob oven page)

- Stacked bricks or dry-laid stone.

Outdoor Brick Oven Chamber Plans

- Masonry Heater Association: mha-net.org

- Wood Fired Pizza Vault – woodfiredpizza.org

- Arched Oven: howtospecialist.com

- Vaulted Arch: considine.net

Check out this article for lots more info and pictures of stone ovens!

Available Ceramic Kits

- Forno Bravo: This site also provides plans for a DIY Pompeii Oven.

- Le Panyol: For both professionals and the individual.

- Mugnaini: You can also find cooking classes available on Mugnaini’s site.

- Superior Clay: They also have mobile kits and Pre-Fab Masonry ovens.

- Vesuvio: Provides a list of questions to consider before buying your oven.

- Jamie Oliver: Curbside delivery from this site is only for UK residents.

Available Concrete Kits

- Artesianovens.com: Contact them for more details on special orders.

- Fire Rock: Has multiple locations throughout the United States of America.

- OmniPro Pittsburg: This company also has outdoor kitchen kits available.

- Chicago Brick Oven: For oven-baked dishes try their recipe section.

- EarthStone: This site offers 3 different residential ovens on their site.

We hope that this article has given you plenty of food for thought as you consider your own backyard brick designs. If you have a brick oven in your own backyard, drop off a photo in the comments below! We’d love to see it in action.

Hello¡

Thank you so much for this webpage. I am in Argentina and I will build an oven. I still do not know the proper size for the dome. I am planing to build a bread oven. Please could you guide me regarding this matter? thanks again.

gambhirah

• I appreciate your Brick Oven site with views of various Brick Ovens.

• Peace-Farms Brick Oven & Bread Baking Project location is in the Kanyawegi area by Kisumu and Lake Victoria in Kenya. The plan is to build the oven, mainly of local brick and metal during June/July of this year of 2015.

• Wood is in short supply; however, corn cobs, stover fuel, is available from our farm development projects. Propane could be used; however, the preference is to use naturally available fuel.

• The goal is to build a brick oven, of a design to be determined, and for the oven to be capable of baking batches of Bread and other baked goods, with the bread being offered for sale at local roadside Farmers Markets.

• In the event of the Brick Oven project being successful, the plan is to duplicate the Brick Oven project in other areas of the Greater Kanyawegi Community by Lake Victoria.

• The plan is to build the brick oven with local materials, and with supervision have local people assist in building the oven. Brick Oven Plans, suggestions, information and advice is welcome from the, “Brick Oven Building Community”.

Hi there… great article, but after skimming through, i did not see any mention of “white ovens”. most of the ones shown are “black ovens”. i am trying to cobble together plans for a combination wood-fired pool heater/brick oven and think that a white oven (fire on the bottom of a cooking chamber on top would be the best. any suggestions where i might learn more about that sort of design would be great…